How we work

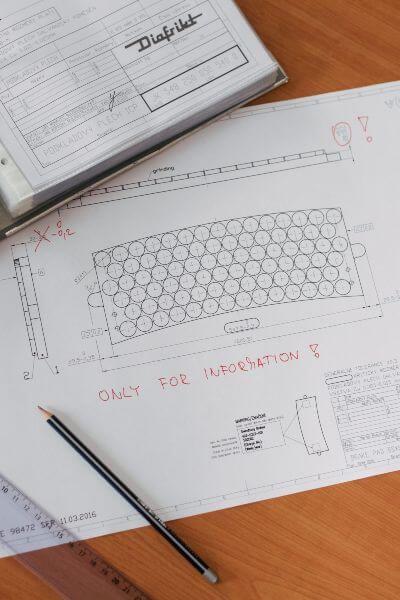

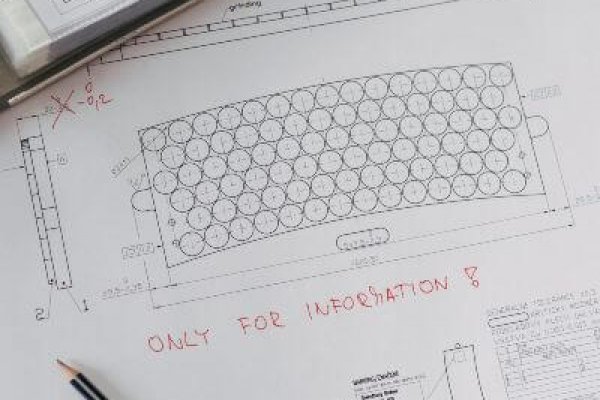

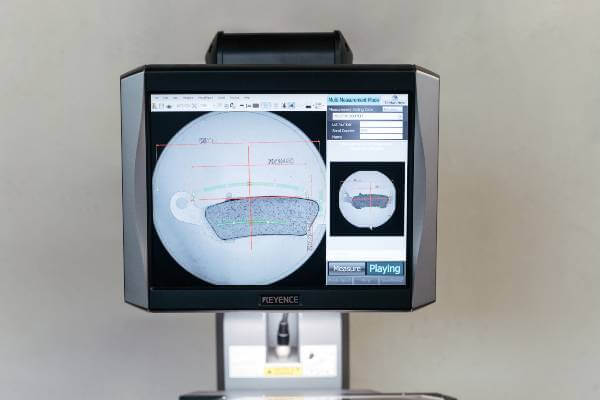

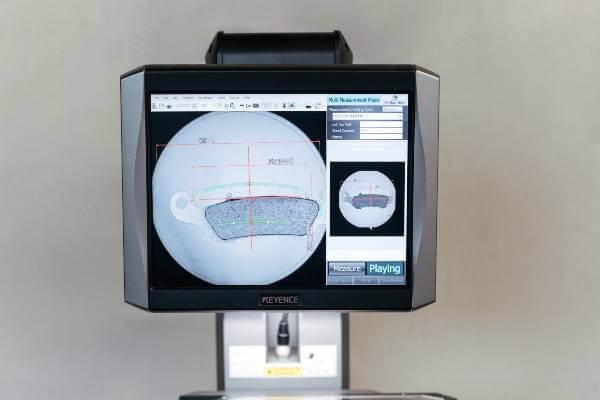

Every new project is being developed with close involvement of our R&D team – no matter whether it is based on a customer inquiry, or on information gathered in our markets.

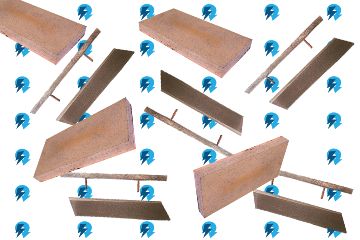

This applies to every step of our development process: from the first calculations & sketches to the final product. We pride ourselves in providing solutions, which are reliable, high-quality and most convenient for the customer. We approach all projects individually and pay them the same caution regardless the size.

Manufacture of a final product does not end the cooperation with our customer. We remain in close contact with the customer and react upon new inquires & requirements. We leverage customers´ feedback in further cooperation.