Brakes and clutches

We manufacture metal-ceramic friction materials / parts for brakes and clutches. Brake and clutch pads of the brand Diafrikt are suitable especially for heavy-duty conditions.

Our products are manufactured using the progressive method of powder metallurgy.

Main advantages of using our metal-ceramic materials for brakes and clutches:

- Long durability and low break pad wear

- High and constant friction coefficient across all weather conditions

- Allow using high breaking pressures

- High thermal conductivity of the friction material

- Low production of dust without emitting health-hazardous particles

- High power transfer at high circumferential speeds

- Resistance to chemicals and operational contaminants

- Environmentally and hygienically friendly

- Suitable for usage in explosive atmospheres

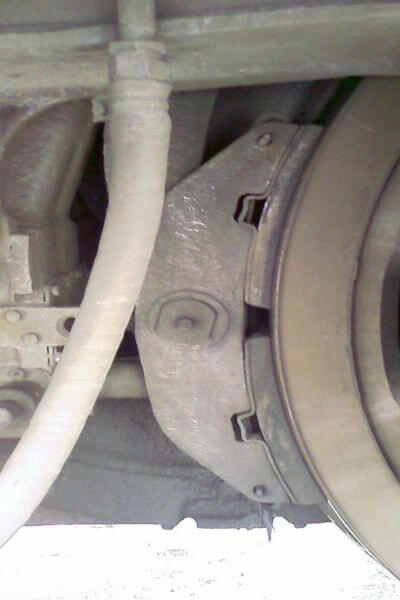

Industrial Brakes

Our metal-ceramic friction materials for industrial brakes are being used in brakes in the wind power plants, heavy-duty cranes, conveyor belts of surface mines, suspended monorail systems in mines, construction and industrial elevators, electromagnetic brakes & clutches, mining excavators, ship winches, mining dumpers, etc.

Industrial Disk and Industrial Drum Brakes

Railway Vehicles

Advantages of our metal-ceramic brakes for railway vehicles are for example:

- Quick bedding-in process and low wear of the train wheels and brake discs thanks to the pattented bedding-in layer

- Lowered noice levels thanks to the above-mentioned bedding-in layer

- Metal-ceramic brakes reliably brake in extremely demanding winter conditions up to -50°C / -58°F

Brake pads for locomotives

Advantages of our metal-ceramic friction materials for locomotives:

- Compared to conventional composite brake pads, the braking effect occurs immediately after the brake pads touch the surface of the train´s wheels, even at a low initial speed.

- They have 3x higher thermal conductivity and thus the rims on the train´s wheels do not loosen.

- The braking efficiency is constant and does not increase with more and more stops, as with cast-iron brake pads.

- They do not disturb the function of electrical railway safety line systems.

Brake pads for disk brakes for vagons

Advantages of our metal-ceramic friction materials for vagons:

- Used up to speed of 250 km/h or 155 mph

- Dissipate heat from the brake discs very well and thus prevent the formation of hot spots and heat spots on the discs.

- A reliably constant friction coefficient enables automatic control of the braking distance in unattended operation of vehicles. Our brake pads always stops safely at the required distance.

- They do not disturb the function of electrical railway safety line systems.

Brake pads for metro / subway

Advantages of our metal-ceramic friction materials for metro / subway:

- On lines where the train sets leave from underground to the surface, it is not necessary to use preheating neither in rain nor in frost, as with composite brake blocks. This results in large savings in traction energy and reduces the need for turning the surface of the train wheels several times over.

- Metal-ceramic brake pads meet the prescribed noise limits.

- Compared to composite brake pads, our brake pads also meet hygiene requirements. When braking, they do not smell of phenols and do not release dangerous nanoparticles that still fly in the air and increase the risk of lung cancer. All the more so because it is an operation in a closed space.

- Compared to cast-iron brake pads, our brake pads do not spark and thus remove the risk of fire.

Brake pads for special railway maintenance vehicles

Advantages of our metal-ceramic friction materials for maintenance vehicles:

- We will design and develop structural and material solutions tailored to the customer’s requirements.

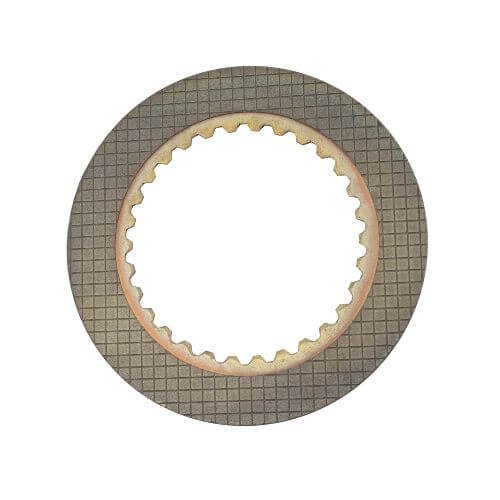

Agricultural Equipment & Machinery

Our metal-ceramic friction materials are used for brakes, clutches and torque multipliers for tractors, winches of forestry vehicles, or centrifugal clutches of small gardening equipment like mowers.

Aircraft

- Na Brnou 169

517 43 Potštejn

Czech Republic

VAT ID: CZ27479943